TurnOuts

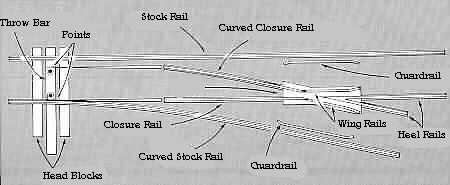

Turnouts

If your railroad doesn't have turnouts, then operation is quite limited. You

can't have industrial yards, crossovers, spurs, or any other trackage that involves switching from one to another. You can only watch it go round and

round. There are many types of turnouts or switches which will improve excitement of operation. However, you have to

take the bad with the good, because chances of derailment and other problems are greatest at the turnouts. Turnouts are classified by number

based on the ratio of the spread to the length of the frog. The angle between

the two heel rails is the determining factor. A number four turnout is larger than a number six. And the larger number means a sharper turn and less

space needed for the switch. For example: An atlas number six takes twelve inches of layout space and a four and a half takes nine inches. If you have

enough space, use six, eight or higher turnouts. Sharper turnouts will reduce the size of car you can run. In order to have less problems at your turnout

point, make sure that the base is solid. If you have any bumps or inclines close to the turnout it could cause distortion of railheads, which may affect

point alignment and make your train derail. When installing the turnout use

as few spikes as possible, the less spikes you use gives less chances of

spreading the rails out of gauge. When driving the nails, always leave space between the nail head and the tie, this allows the turnout to float above the

supporting surface. This does not force the track out of level and allows for easy changing.

Be careful if ballists turnouts, it is easy to ballist to interfere with the points,

the throw rod, or the frog. Ballists should not be above tie level.

Often check to make sure turnouts work properly, dusting away any dirt that

may lodge between the points. The points should always be sharp. Blunt

points cause cars to bump into the end and rollover, causing derailment. Also, make sure the points remain level with the rails. Finally, make sure

the rails are clean to insure good electrical contact. This applies to the inside

of the points particularly when they conduct electricity to the branching

track. Clean point sides with fine sand paper folded in half.

Hope the info helps, look for other sections in upcoming months !!!

RETURN

Copyright ©1995-2004 HobbyLinc. All rights reserved. Images and Descriptions are representative only, actual items may vary. Prices subject to change without notice.